Pre-Engineered Buildings

A pre-engineered building (PEB) is a structure that is designed, engineered, and fabricated in a factory before being transported to the construction site for assembly. It is a type of building construction that utilizes standardized and pre-fabricated components to expedite the construction process and enhance efficiency.

PEBs are typically made of steel and are commonly used for industrial, commercial, and institutional applications. The design of a pre-engineered building involves the integration of various building systems, including the primary framing, secondary framing, roofing, wall panels, and other components. These components are manufactured off-site and then transported to the construction site for assembly.

One of the key advantages of pre-engineered buildings is their speed of construction. Since the components are pre-fabricated, the on-site assembly process is streamlined, resulting in faster project completion compared to traditional construction methods. Additionally, PEBs offer design flexibility, allowing for customization based on specific requirements and building codes.

PEBs are known for their structural strength, durability, and cost-effectiveness. The steel components used in pre-engineered buildings provide excellent strength-to-weight ratios, making them capable of withstanding various loads and weather conditions. The use of standardized components also helps in reducing material waste and optimizing cost efficiency.

Overall, pre-engineered buildings offer a practical and efficient solution for construction projects that require speed, flexibility, and cost-effectiveness. They have become increasingly popular in sectors such as warehouses, factories, distribution centers, retail spaces, and sports facilities.

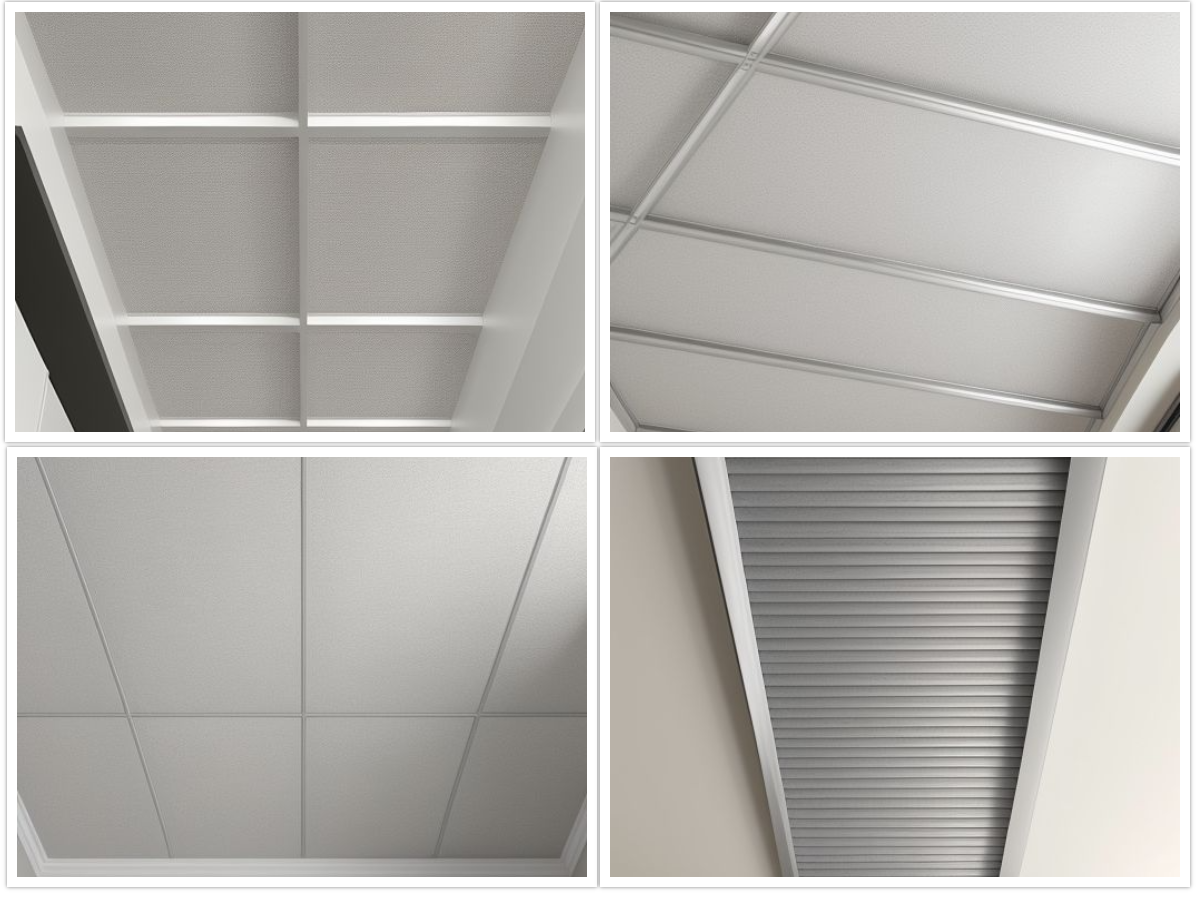

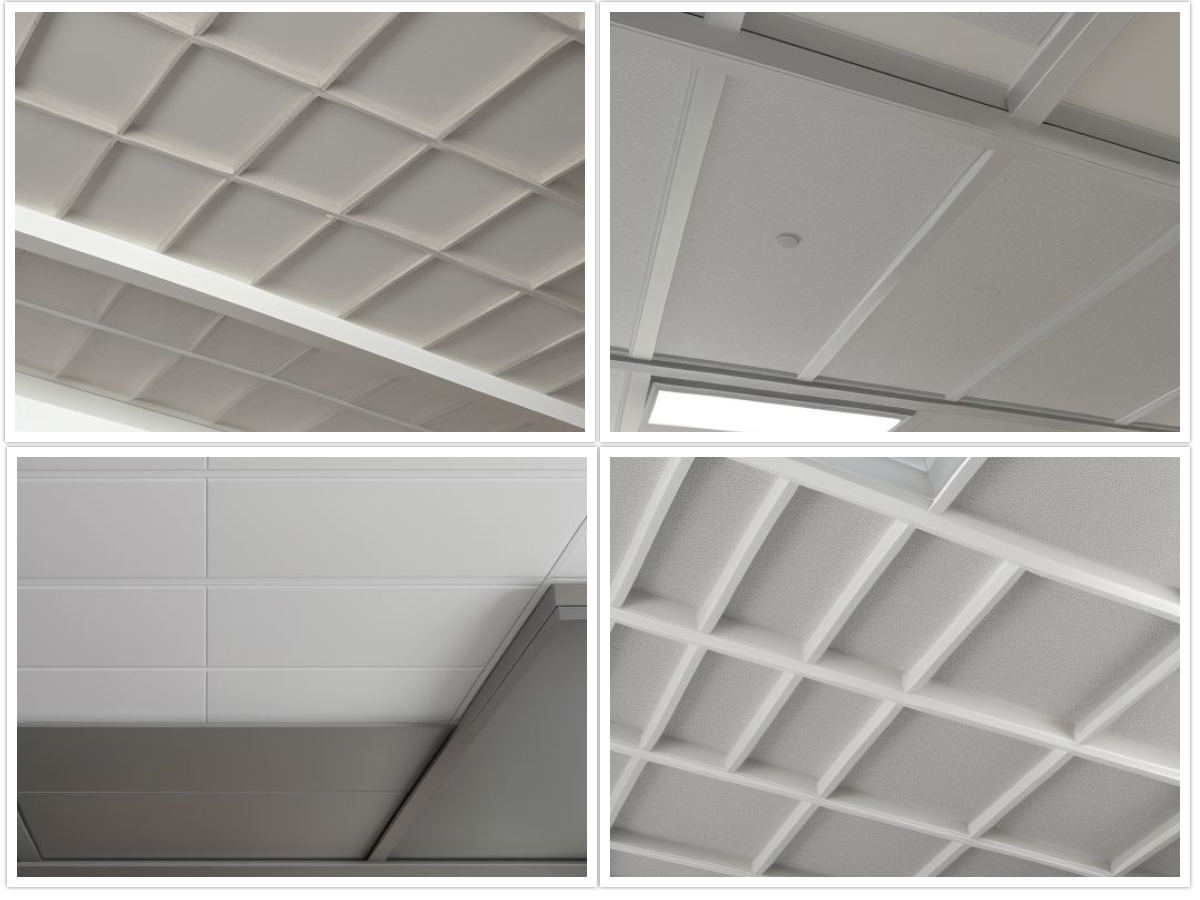

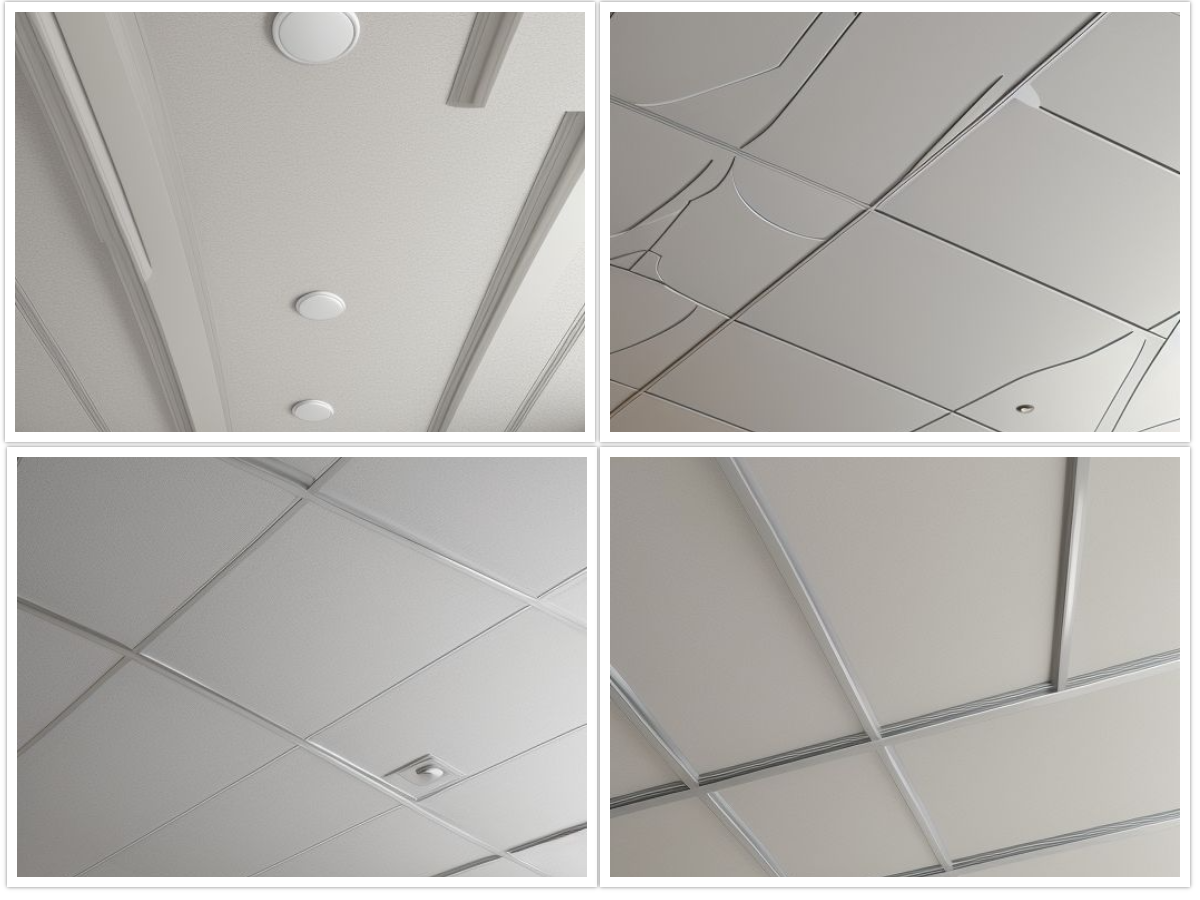

Metal False Ceilings

Metal false ceilings, also known as metal suspended ceilings or metal drop ceilings, are architectural elements used to create a finished look in the upper part of a room while providing functional benefits. They are often installed below the main structural ceiling, leaving a space or "plenum" between the two.

Our clients can avail from us an outstanding collection of Metal False Ceilings that are fabricated using superior quality material. The metals, such as aluminum, galvanized steel and stainless steel, used for fabrication are procured from a reputed vendor base. Further, we make use of latest technology equipment and tools that facilitate the production of a flawless range of false ceilings. These are available to the clients in various sizes and colors as per their requirement and demand.

Here are key features and aspects of metal false ceilings:

Materials : Metal false ceilings are typically made from aluminum, steel, or other metal alloys. These materials offer durability, resistance to moisture, and a sleek, modern aesthetic.

Components : The structure of a metal false ceiling usually consists of a grid or suspension system, which includes main runners and cross tees. Metal panels, often perforated or with designs for aesthetics and acoustic performance, are placed within this grid.

Design and Finish : Metal false ceilings come in various designs and finishes, offering a range of aesthetic options. Common finishes include powder coating, paint, or even metallic finishes to complement the overall design of the space.

Acoustic Properties : Some metal false ceilings are designed to enhance acoustic performance by incorporating perforations or adding acoustic insulation in the plenum space. This is particularly important in commercial spaces, such as offices or auditoriums, where controlling sound is crucial.

Fire Resistance : Metals are inherently fire-resistant, adding a safety element to the ceiling structure. In some cases, additional fire-retardant coatings may be applied.

Ease of Installation : Metal false ceilings are relatively easy to install, and their modular nature allows for flexibility in design. This makes them a popular choice for both new construction and renovations.

Maintenance : Metal ceilings are low maintenance and easy to clean, which is advantageous in commercial settings where hygiene is crucial.

Lighting Integration : The design of metal false ceilings often allows for the integration of various lighting fixtures, such as recessed lights, pendant lights, or other types of lighting elements.

Sustainability : Some metal false ceilings are recyclable, contributing to sustainability efforts in building design.

Applications : Metal false ceilings are commonly used in commercial buildings, offices, airports, hospitals, and other spaces where a combination of aesthetics and functionality is desired.

Porta Cabins

A porta cabin, also known as a portable cabin or modular cabin, is a type of temporary or portable structure that is designed for various uses, such as office space, accommodation, storage, or other purposes. These cabins are typically prefabricated and can be easily transported to different locations. They are commonly used in construction sites, remote areas, or places where a temporary structure is needed.

The term "porta cabin" is derived from "portable cabin," emphasizing the ease with which these structures can be transported and set up at different sites. They are a practical solution for temporary accommodation or office needs in situations where a permanent building may not be feasible or necessary.

Porta cabins are known for their versatility, quick installation, and mobility. They are often made from materials like steel, aluminum, or a combination of both, providing a balance of durability and portability. These cabins can be customized to meet specific requirements and may include features such as insulation, air conditioning, plumbing, and electrical wiring. The portability and modular nature of these cabins make them convenient for temporary or semi-permanent use in situations where a quick and flexible solution is needed.

Common applications for porta cabins include construction site offices, guardhouses, classrooms, healthcare facilities, and housing for workers in remote locations. They are also used at events and festivals as temporary structures for ticket booths, information centers, or as dressing rooms for performers. The versatility and ease of installation make porta cabins a popular choice for temporary space requirements.

Hi-Rib

- Hi-Rib profies is 1020mm wide coverage with 28-30mm deep ribs at 200-250mm centre to centre with two/three stiffeners in between the rib.

- Hi-Rib profile incorporates male/female ends with fill return leg & anti-capillary flute at side-lap thus ensuring leak proof sheeting capable of efficient water drain out.

- The profile is also available in crimp curve from the semi-circular/arched roofing and flashings.

Fixing Procedure :

Lift sheets onto roof supports with ribs up and all with overlapping ribs (female) facing towards starting edge. To commence fixing place the first sheet in position with the female rib in line with other building elements and fasten as recommended. Lap the female rib (with turned down free edge) of the second sheet over the make rib (with turned-out bottom edge) of the first sheet and insert recommended side lap fasteners to hold the lap firmly in place before fastening the second sheet to support. Follow the second sheet procedure for subsequent sheets.

Enqire Now

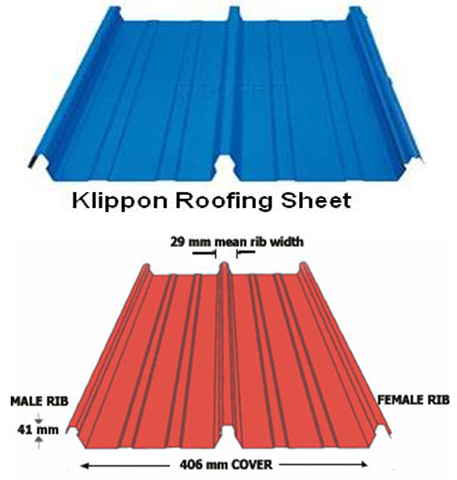

Klippon

Kliplock profile is designed to be fixed to roof purlin or wall girt with fixing clips which concealed during insulation and require no fastening holes through the shed. As Kliplock fixing method no screws are visible so there is no screw penetration. The clips are fixed directly on the support with only 2 nos. fasteners per clip thus provide positive engagement in the ribs of the profile.

Klipon Fastning Method :

Klippon steel cladding is designed to be fastened to roof purlins or wall girts with fixing clips which are concealed during fixing and do not require any fastening holes through the steel sheets.

The clip for fastening Klippon steel cladding requires only two fasteners per clip and provides an easy, positive engagement in the ribs of the profile.

The two fasteners are inserted only through the two punched holes. Four dimples are also provided in the clip but these are for auxiliary fasteners only.

Because of the concealed clip fixing method, no fastening screws are visible and there is no screw penetration through the external sheeting. Concealing fixing also offers and advantage of security. Entry into the premises by unscrewing of roof and wall cladding sheets is not possible. Klippon can be used for roofing large span factories, warehouses, commercial, educational, institutional, domestic and recreational buildings.

Advantage of profiles :

- Roofing in Industrial, commercial, residential and various other markets.

- Strong profile to stand High wind pressure.

- Supplied in either custom cut or any length.

- Available in wide range of Galvalume, Pre-painted galvanized steel, aluminium etc.

- Economical solution for builders.

- Can be fixed on existing shed.

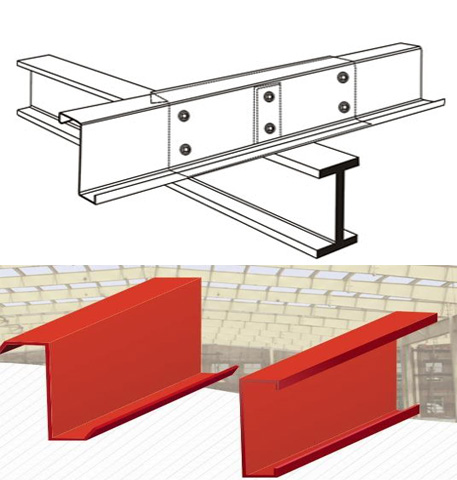

Z purlins

Z purlins are most unique cold roll formed sections used to fix roof and side claddings. The advantage of using Z purlins is unlimited-depth the thickness option gives the designer the required freedom to design most economical purlin.

The higher Zxx value gives more stability in lateral direction and thus minimizes saving.

Designer can select different thickness Z purlin with similar depth for the same structure, which ensures overall economy for the structure. Sleeved Purlin system ensures continuity and rigidity.

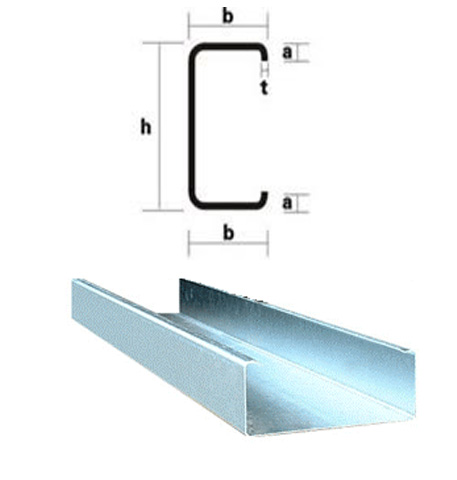

Cee Purlins

“ CEE ” Purlins can be used in place of Z purlins or conventional hot rolled C channels or IS angles or tubes for fixing roof or side cladding.

This new time saving bridging system with a comprehensive range of accessories available, provides a complete, easily erected system. This system provides efficient light weight, economical roofing and cladding supports for framed structures.

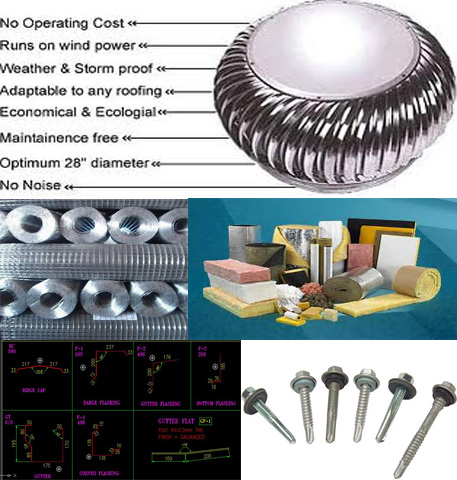

Accessories & Flashing

In addition to the profiled sheets, Paramount also supplies factory finished Cold-formed flashings, cappings & trims such as: Barge Boards, corners, Drip ends, Gutters, Ridge Capping, Apron flashings etc.

Paramount also supplies Ridge-Vent, Roof Monitor, Ventilator, Louvers, Contour-matched skylight panels, FRP/Polycarbonate, Foam-Fillers, sealing, roof curbs etc. as per requirements.

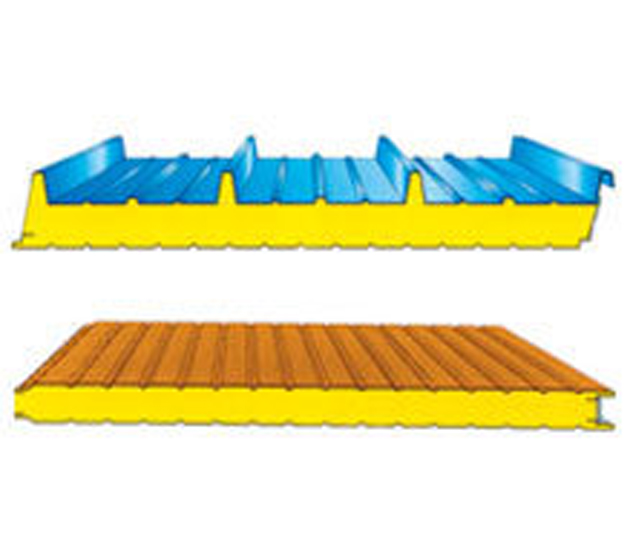

puf sandwich panels

Insulated Sandwich Panels offers an affordable range of sandwich puf panels for roofing, wall cladding and cold room. These insulated sandwich panels consists of two facings of relatively thin metal profiled sheet of high strength, which is relatively thick and light with required stiffness. The facings are of aluminum or steel.

Dimensional Specification

| Thicknesses | 30 to 120 mm |

| Width | 1000 mm to 1200 mm |

| Maximum Length | 15 meter |

Advantages :-

- High load bearing capacity at low weight

- Excellent thermal insulation

- Absolute water and vapour barrier

- Excellent air tightness and free of thermal bridgeswhich results in considerable energy

- Resistance to weather and aggressive environments

- Ease of installation

- Long life and very low maintenance cost

- Easy repair and replacement in case of damage

- Good sound insulation

- Reasonable fire reaction and resistance